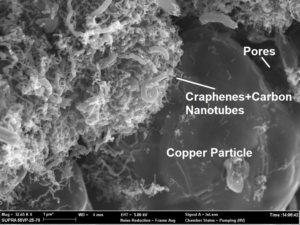

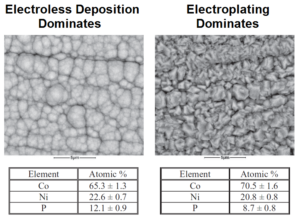

Hybrid Electro-Electroless Depsosition (HEED) is the Electrochemical reduction of distinct metals or alloys by independent processes within a single electrolyte. The wet electrochemical metal plating process combines both electroplating and electroless deposition to create an environmentally less-harmful means of producing metal layers.

For example, Nickel (Ni) and Cobalt (Co) normally require 2 distinct electrolytes and associated rinse baths to plate a modulated multi-layer deposit (deposit having alternating Nickel and Co layers). With HEED modulated Ni-Co multi-layers of various purities can be deposited from a single electrolyte!

It is well known that alternating metal layers have hardness greater than either constituent metal depending on the individual layer thickness. Developments in the formulation and technique have produced layers of >95% purity as well as opened the door to new hardened alloys. Applications of the coatings include wear resistance, corrosion resistance and conductive electronic applications.