Aluminum is an inexpensive, robust, and highly machineable metal suitable for a number of applications. The largest failing with Aluminum is the lack of electrical conductivity to be used in grounding and electrical applications.

Current copper plating technology requires an expensive multi-stepped stepped process comprised of several dozen steps to clean, rinse, and plate the aluminum part. Worst still the process is far from bullet-proof with a final examination discarding some parts, in the worst case as much as 20% of the parts.

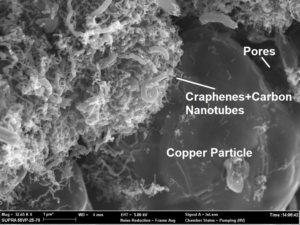

Using proprietary techniques for thin film plating, largely electroless copper can be deposited on aluminum surfaces. The tunable process allows for selective and non-selective deposition by controlling the methods, locations, and levels of pre-treatments.

Coating Properties

Good Adhesion

Conformal

Pure Cu

Direct on Platen Material

Selective Thread Plating

Single Bath (Electrolyte)

Electrolyte formulations can be adjusted to deposit various copper alloys including those with nickel and tungsten to enhance physical properties. The techniques are used generate an in-line, cost-effective, environmentally friendly coating process.

Additional Resources:

https://www.sharrettsplating.com/blog/electroplating-defects-issues/